From cultural connections to regional palates – a Sapporo-based sake brewer’s take on the intricacies of sake brewing

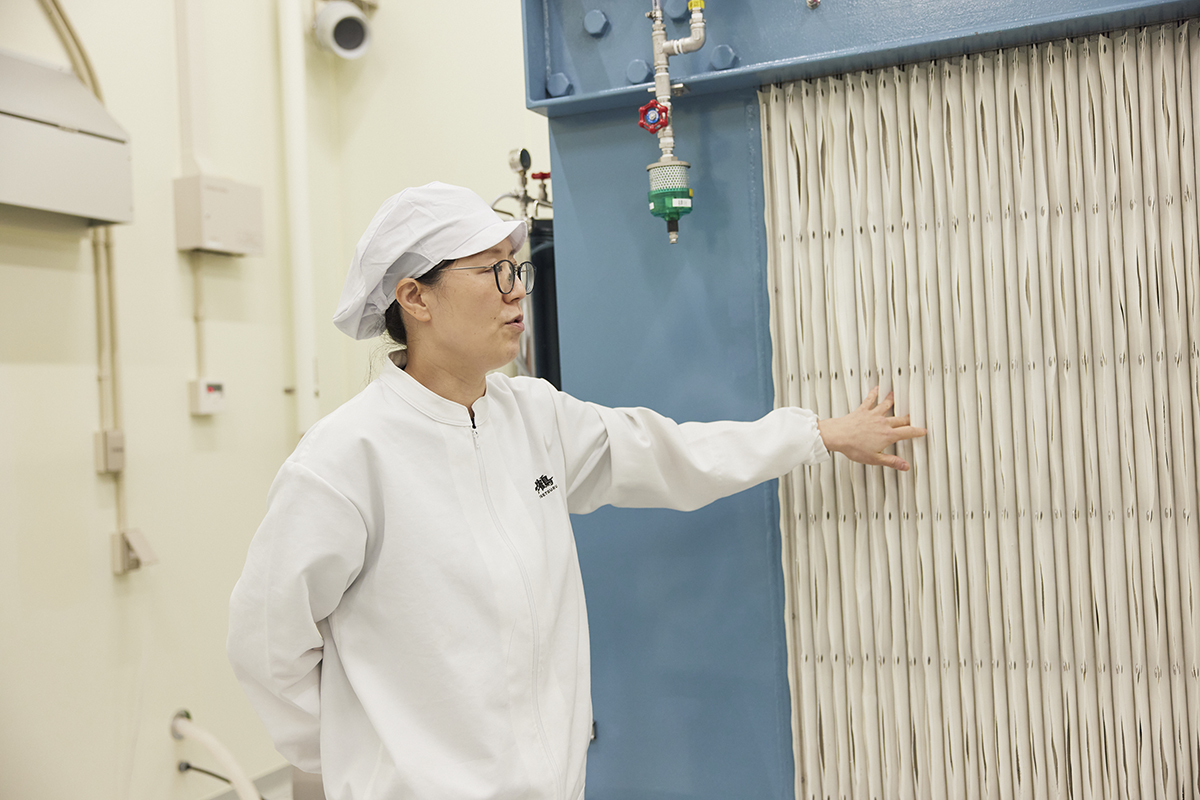

A head sake brewer fascinated by microorganisms, using all five senses to fine-tune exquisite sake Satoko Ichizawa

An insatiable curiosity about microorganisms and a drive to learn a trade led Satoko Ichizawa to the complex world of sake brewing. She cut her teeth at a local sake brewery in Kushiro before taking up the reins at Chitosetsuru in Sapporo. For the past eight years, she has been carefully brewing delicious sake made from local Hokkaido rice and the pristine subterranean waters of the Toyohira River, which flows through central Sapporo.

I became captivated by sake brewing after watching a head sake brewer’s work

I’ve always wanted to learn a trade, and that, coupled with my curiosity about microorganisms, led me to study fermentation science at college. After graduating, I spent three years working as a brewer at a microbrewery in my hometown, Kushiro in eastern Hokkaido. I moved on from beer to sake with a job at the local sake brewery, where I worked under a Nanbu toji – head sake brewer of the Nanbu technique from Iwate prefecture – who had come to Kushiro to work for a year. As I watched this toji being involved in all aspects of the sake brewing process, which takes half a year – from buying the rice to the final stages of production – I knew that my future lay in sake brewing. I was fascinated by the way of life and work of a toji, but I also wanted to take it one step further. Visiting tojis, like the one I watched, generally leave after the sake is brewed. I decided that I want to take responsibility for the sake right up until it reaches the customer’s mouth, so I also oversee the packaging and shipping process. Fast-forward to today and I’ve been involved in sake brewing for more than 20 years, the last eight of which I’ve been working in Sapporo as the toji at Chitosetsuru, Hokkaido’s oldest sake brewery, now in its 151st year.

Sake brewing is incredibly complex – there are no simple answers

Sake is made from water and rice: the rice is washed and steamed, yeast is used to convert the rice starch into alcohol, and koji, created by koji mold multiplying, is used to dissolve the rice to make sake. The ingredients and recipe might seem simple on the surface but the production process is very complicated and labor intensive, especially compared to other brewed liquors like beer and wine.

Where wine is fermented by placing grapes and yeast in a tank all at once, sake is brewed three times in the same tank. In order to keep the yeast alive, steamed rice and koji are added at each cycle of the brewing process in a perfect balance, which can produce as much as 20% alcohol. I’m working with microorganisms so I have to be very careful about all kinds of variables – so much so that I avoid eating certain foods with live cultures like my favorite natto (fermented soybeans) because I can’t run the risk of that bacteria making it into the mix. It’s killing me, but it’s the kind of sacrifice I have to make.

The complexity of sake brewing is what makes it so fascinating – it always keeps me on my toes. There’s a lot of skill and wisdom involved in teasing out the perfect formula. I enjoy using my imagination to formulate the brewing process of each batch of sake.

There is no “I” in team

As a toji, it’s my job to be part of every single aspect of the sake brewing process. There’s no doubt that making good sake depends on the skill of the toji, but I never underestimate the importance of teamwork – I can’t do this on my own. To ensure that we’re brewing the best sake possible, I strive to create a healthy work environment and choose the right team for the job – this in itself is no mean feat.

Along with supporting my incredible team, I’m very particular about the koji – the backbone of sake flavor. I spend three days making koji, and use all five senses to fine-tune the flavor. There are many decisions I need to make, for example what kind of koji should we make to dissolve rice that’s not in the best condition. It’s not like I follow a manual either, I have to conjure up the ideas in my head. This process is so intricate that it’s impossible to reproduce the flavor by simply analyzing the ingredients and using the same quantities. There’s a great variety of flavor across the sake spectrum, which differs between breweries, depending on variables such as the water they use, and the region where they are located. You’ll even find diverse flavors within Hokkaido. Each region is characterized by different flavors of rice and climates, and this affects the local palate, with people often preferring sake made with local rice and water. At Chitosetsuru, we are making sake with local Hokkaido rice and the subterranean water from the Toyohira River in Sapporo. Everything we do is tied to our local roots – we even created an award-winning sake in the image of Sapporo’s official tree, the lilac.

We’re blessed by the pristine subterranean waters of the Toyohira River

Our core feature is that we use rice from Shintotsukawa Town in western Hokkaido and subterranean water from the Toyohira River, which flows by our brewery here in central Sapporo. The subterranean waters are incredibly clean and soft with a mild taste that goes well with the rice. It’s amazing that such pristine water flows through the center of the city. In January 2023, we built a new brewery even closer to the river because we can’t tear ourselves away from this incredible source, which contains few foreign particles and requires little processing, making it perfect for sake brewing. As much as sake is tied to local ingredients, it’s also inseparable from Japanese spirituality (Shintoism) and culture – it was originally made to be offered to the gods. I make sure that I greet the gods at the Shinto alter in the brewery every day. Shinto rituals are an important part of Japanese culture, and knowing about this connection can deepen your sake experience.

I want to share the world of sake with more people so recently we’ve opened the factory to tour groups of around 10 people. Visitors can also sample various sakes and enjoy sake kasu-flavored soft serve ice cream at the Sake Museum. Enjoying the unique flavor of sake made with Hokkaido rice and water is a great way to get a taste for Hokkaido!